Conversions

Need a custom clutch kit to suit your engine or gearbox conversion? We can help.

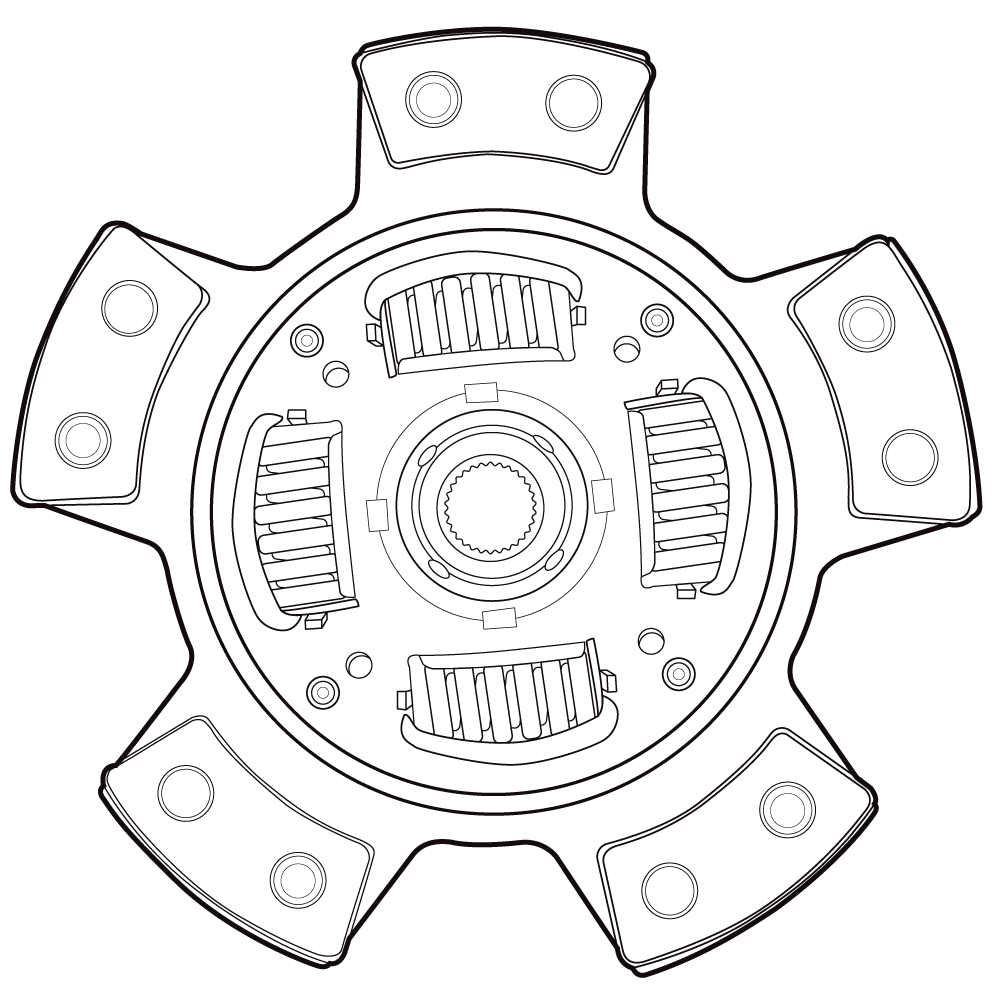

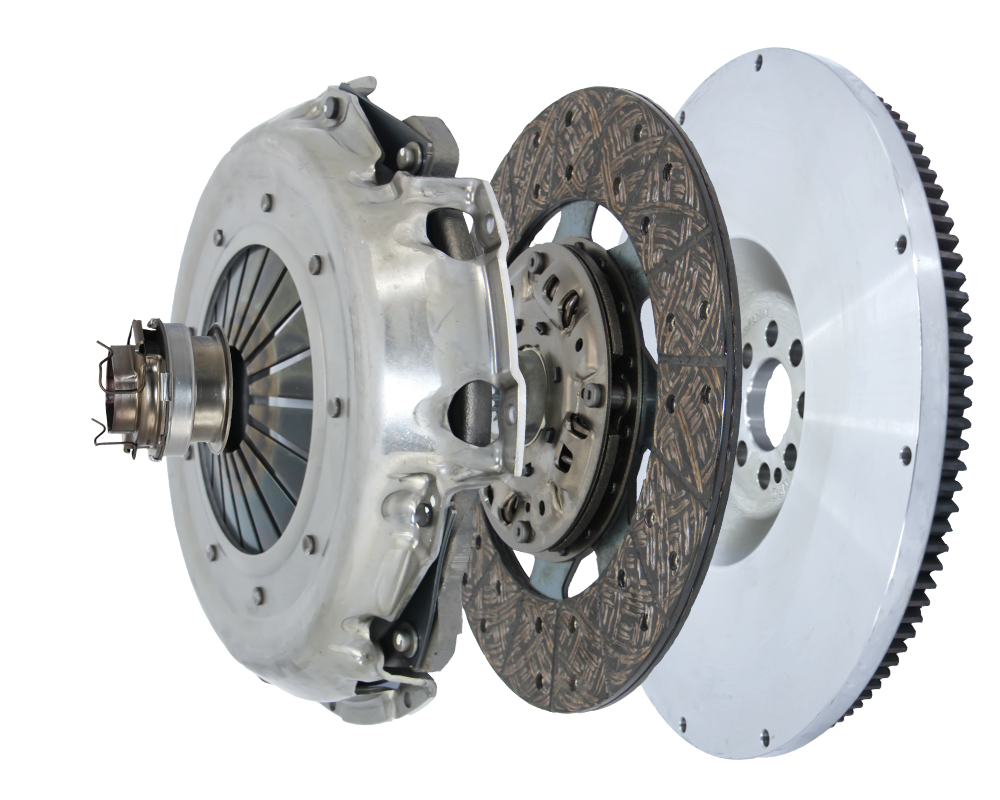

Conversion Clutch Kits

We specialize in developing kits to cater for common or unique conversions.

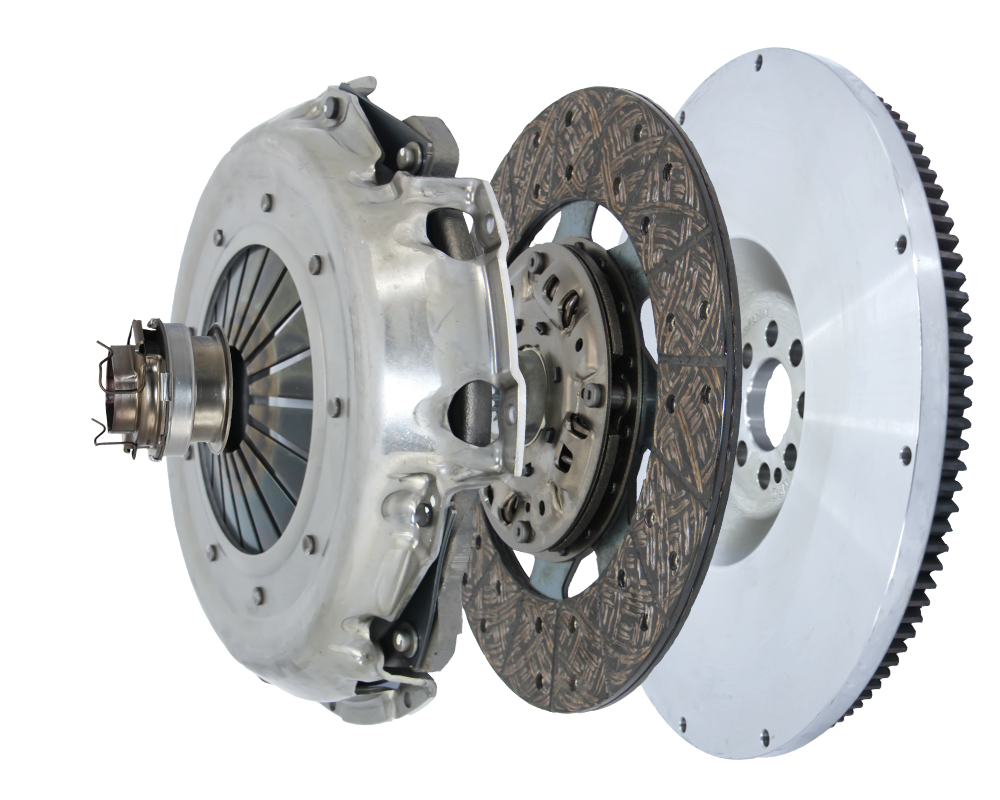

Be mindful selecting your conversion kit – all conversions aren’t created equally! For the clutch to operate correctly and last, alignment between the engine and transmission is crucial.

Simple things to check during fitting:

- Does the input shaft fit the spigot bearing?

- Does the spline of the input shaft, engage the clutch spline?

- Does the guide tube for the bearing clear the spline of the clutch plate?

- Does the release bearing carrier and bearing combined with the clutch fork, all sit in the correct position relating to the bell-housing window and clutch height?

- The clutch fingers move toward the gearbox. As the disc gets thinner, the carrier and bearing needs to be able to move back and allow the clutch to wear fully (roughly 6mm minimum)

- Select the bearing to suit the clutch fingers.

- General rule: flat fingers need roll tip bearing and roll tip finger need a flat bearing

- Finally, do you have enough travel to disengage the clutch? Master and slave combo needs to be selected carefully.

Some of the common conversions include:

BARRA / PATROL

We will need to know:

- Brand of adaptor kit

- If Dellows - which version?

- Power / Torque

- Intended use of vehicle

BARRA / LANDCRUISER

We will need to know:

- Brand of adaptor kit

- If Dellows - which version?

- Power / Torque

- Landcruiser model code (e.g., FZJ80)

- Gearbox / Vehicle model gearbox is from

- Intended use of vehicle

LS ENGINE / PATROL

We will need to know:

- Brand of adaptor kit

- If Marks adaptors - which version?

- Power / Torque

- Intended use of vehicle

SR20DET / RB 5spd & Z32 5spd

(There are many different adaptor kits available. Some require the taller S15 6spd style flywheel and some require the lower S13/14 5spd style flywheel). We will need to know:

- Brand of adaptor kit

- Power / Torque

- Intended use of vehicle

1JZ & 2JZ / AR5

(There are many different adaptor kits available. Some work with the factory style AR5 internal slave cylinder and some work with a factory R154 style pull type clutch). We will need to know:

- Does your adaptor require the pull type R154 style clutch, or does it utilize the AR5 style internal slave cylinder?

- Brand of adaptor kit

- Power / Torque

- Intended use of vehicle

1JZ & 2JZ / T56 GM26 SPLINE

(There are many different adaptor kits available. Some require the taller 6spd style flywheel, and some require the lower 5spd style flywheel). We will need to know:

- Brand of adaptor kit

- Power / Torque

- Intended use of vehicle

Select from our wide range of clutch kits available on our website, or contact us directly for a custom project or conversion.

Need help? Start by filing out our Enquiry Form, and we can be in contact soon to discuss your project.

Alternatively, if you need any advice do not hesitate to contact our friendly sales team.

For Quality Clutches Contact Us Today!

For general enquiries and information, give us a call on 07 3420 3446 and our friendly staff will be happy to help!